SENSOR Test

What are Magnetic Sensors?

A magnetic sensor detects the strength of magnetism and geomagnetism generated by a magnet or current. They convert magnetic field or magnetically encoded information into electrical signals for processing by electronic circuits. They are becoming more and more popular because they can be used in many different types of applications such as sensing position, velocity, or directional movement.

There are several different types of magnetic sensors:

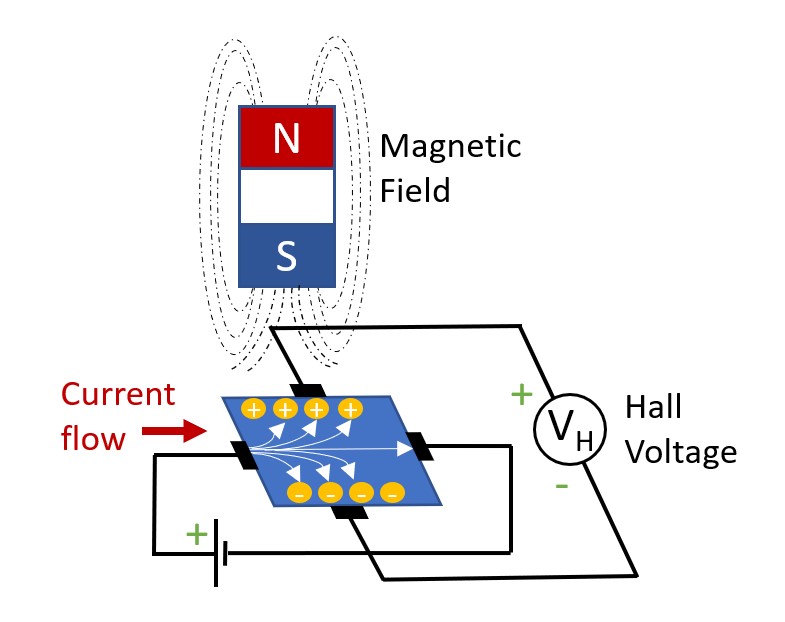

Hall Effect Sensors

Hall effect sensors are built with a current-carrying strip conductor on a semiconductor substrate and is activated when placed into magnetic flux, creating an electrical voltage by Hall-effect perpendicular to the current flow direction. Hall sensors are widely used in automotive and industrial applications.

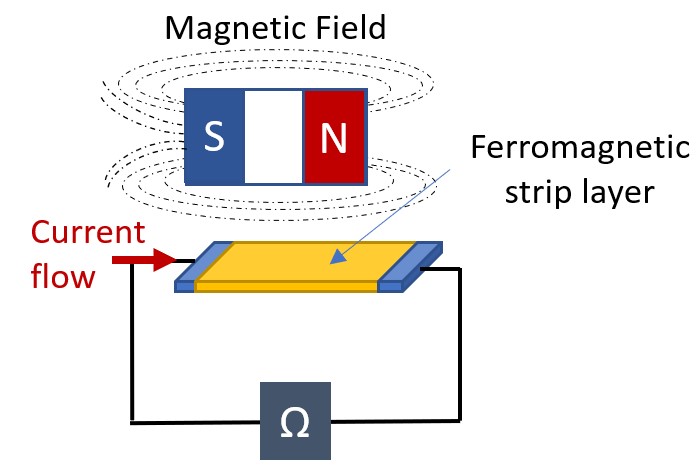

AMR Sensors

Anisotropic Magneto Resistance (AMR) sensors are composed of an anisotropic magnetic strip line having the equivalent resistance dependent with the angle of magnetization direction and the electrical conduction direction. AMR sensors present a relatively low magnetoresistance (MR) ratio compared to other MR sensors. They are used in industrial, commercial, and spatial applications as movement or angle sensors as well as Earth magnetic field sensors.

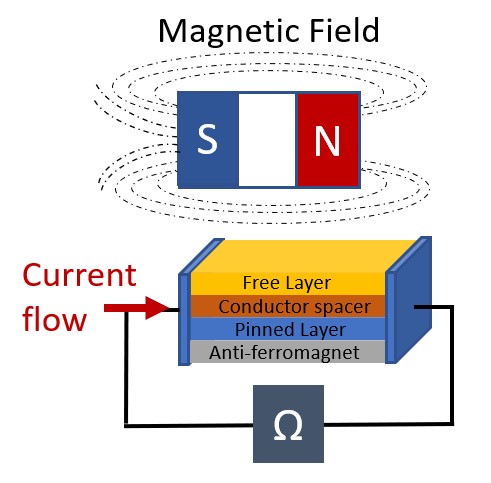

GMR Sensors

Giant Magneto Resistive (GMR) sensors are composed of a sandwich of thin magnetic layers separated by interface conductive layer. The device has two states of resistances. When the two magnetic layers have parallel magnetic orientation, the device has a low state of resistance and a high state of resistance when the two layers have opposite orientations. GMR sensors are accurate magnetic field sensors with good temperature stability. They have been widely used in Hard Disk Drive (HDD) industry as well as in industrial applications.

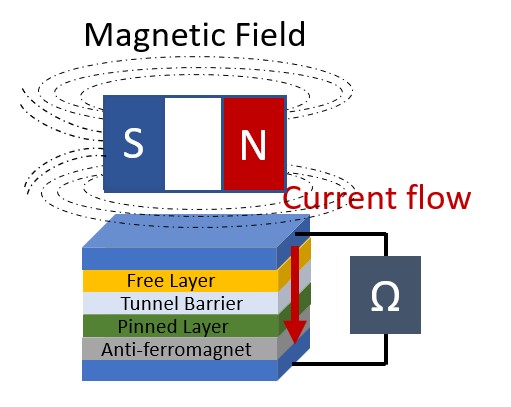

TMR Sensors

Tunnel Magneto Resistive (TMR) are composed of stack of ferromagnetic materials separated by a tunnel barrier. The resistance of the TMR device is dependent with relative angle between two ferromagnetic layers. Compared to other families of magnetic field sensors, TMR sensors have a better signal-to-noise ratio and score with unprecedented accuracy and very low power consumption. TMR sensors offer reliable and stable performance over temperature and the lifetime of the sensors. As a result, TMR sensors are preferred in very demanding applications.

What are magnetic sensors markets and applications?

The applications of magnetic sensors are many, including automotive, consumer electronics, electromedical systems, telecommunications, control of industrial processes. Traditionally used as compass to detect Earth magnetic field, they are now used in multiple environments to detect movement, rotation or to measure angle.

What is the future of Magnetic sensors?

The high usage of magnetic sensors in new navigation devices, presence detection (building automation-related applications), medical areas, automotive sector, robotics, and factory automation are leading to a paradigm shift in the magnetic sensors market around the world.

- The increase in demand for IoT and the production of consumer electronics, electric and hybrid vehicles, and high-quality sensing devices, globally, are influencing the adoption of magnetic sensors across several end-user industries.

- An increase in the adoption of robotics for factory automation, owing to Industry 4.0, is driving the need for magnetic sensors for various safety applications in the global market. The development in the services sector and high growth rate of data center and cloud providers are further augmenting the demand for these sensors.

- The demand for magnetic sensors is anticipated to increase in the automotive industry. Sensing devices are increasingly being used in this industry to improve vehicle convenience and fuel efficiency. Also, mandatory regulations by government bodies, such as the installation of safety equipment and sensing elements in automobiles, are estimated to create significant opportunities.

What are the Magnetic Sensors market projections?

According to market projections, the global magnetic sensor market was valued at USD 2283 million in 2019. It is expected to reach USD 3258 million in 2020, and 12 billion by 2025, registering a CAGR of 51% over the forecast period 2020 – 2025.

What is Hprobe’ contribution to the success of Magnetic Sensors?

As an automatic test equipment (ATE) provider with a unique expertise, Hprobe offers IC manufacturers with a turnkey solution that will accelerate magnetic SENSOR product development, ensuring a successful ramp-up.

Testing time is a key performance indicator in production and a strong added value to reduce development time. Building the optimal wafer test equipment dedicated to SENSOR technology and products, with maximum flexibility and shortest testing time, brings significant value during the development phase, and drastically reduces time-to-market (TTM) to high-volume manufacturing (HVM). Hprobe’ solutions fulfill the needs for both flexibility and performance, therein supporting engineers on their long road from technology release to production control and monitoring.

How do Hprobe products operate?

The sensors are measuring the magnetic field to extract information on the position, the angle, the strength, and the field direction. The outcome of this measurement is data related to the motion of a part or of a current flowing. To validate chip products for end applications, the test is done at wafer level by doing electrical probing while varying the magnetic field above the wafer.

The wafer-level test is done by:

Applying a fast-settled static magnetic field in any direction of space 1D, 2D or 3D and measuring the output electrical response of the sensor.

Applying a variable magnetic field swept fast in amplitude or angle to sort the products at high throughput, enabling full test coverage on the wafer while limiting the cost of test.